SERVICES

- Design Build of Clean Room Systems

- Modular Construction

Clean Room Design, Installation, & Certification

Clean Rooms Design & Classifications

Cleanroom Classifications

The classification of air cleanliness is determined by the number and sizes of particles allowed in the cleanroom, along with air changes per hour. The correct quantity of HEPA grade filters will be selected using air changes per hour, as the most effective method to achieve the desired ISO or US Federal 209 Class.

ISO |

Federal Standard 209E |

Air Changes Per Hour |

| 1 | No Equivalent | 500-750 |

| 2 | No Equivalent | 500-750 |

| 3 | 1 | 500-750 |

| 4 | 10 | 540-650 |

| 5 | 100 | 430-600 |

| 6 | 1,000 | 150-210 |

| 7 | 10,000 | 50-90 |

| 8 | 100,000 | 18-35 |

| 9 | No Equivalent | – |

Using state of the art latest equipment, and operated by qualified testing engineers, we offer the complete range of performance testing including:

-

HEPA Filter Leak Integrity Testing

To ensure rooms are supplied with properly HEPA-filtered clean air.

-

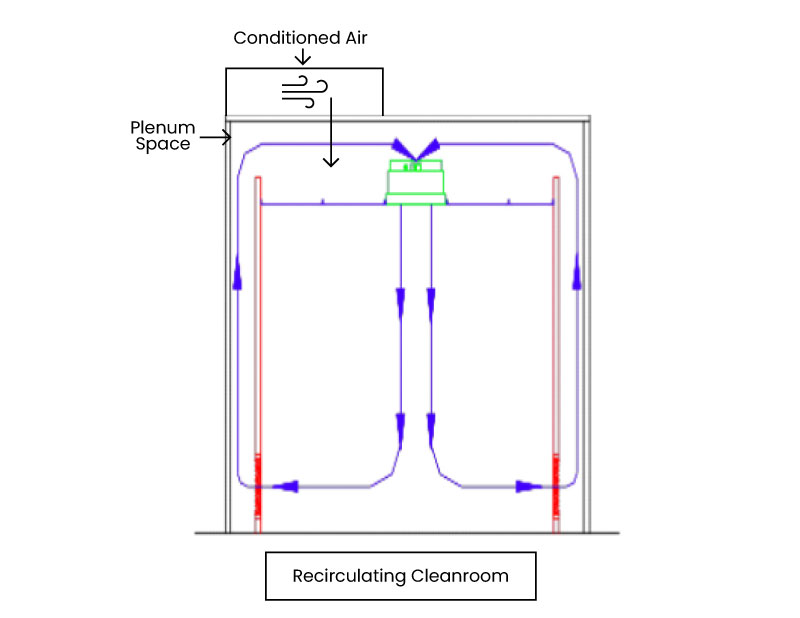

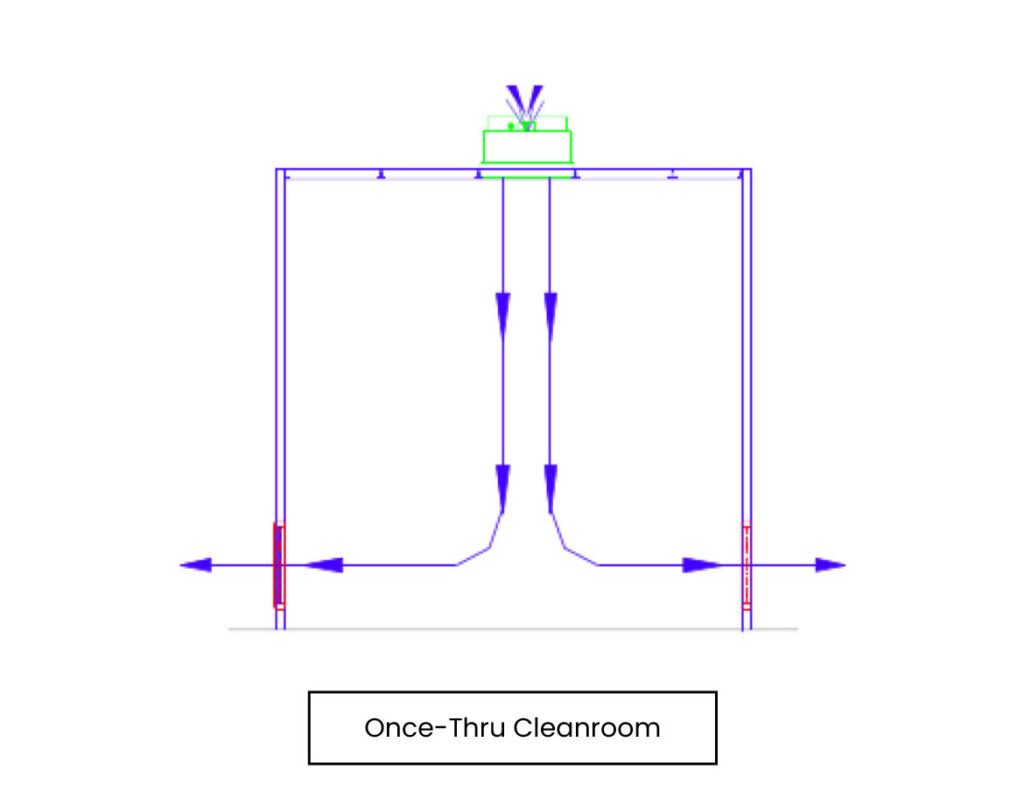

Airflow Analysis

(Room Air Patter / Air Exchange Profile / Air Volume)

To verify the air changes per hour (ACH). -

Particulate Classification

To verify and determine the ISO cleanliness levels of the rooms.

-

Room Pressure Differentials

To determine the airflow directions between specified cleanrooms and the overall facility.

-

Data Mapping / Sample Site Identification

To document the current data for rooms / areas tested.

-

Written Report

Documents provided following cleanroom certification will include a summary of all results and the defined acceptance criteria for each test conducted, site specified test methods, drawings detailing the cleanroom layout showing the locations of test measurements, raw data collected, test certifications and calibration certificates for all test equipment used.

Why Trust Clean Rooms Ability?

Building a rapport is paramount for the success of your clean room. Clean Rooms Ability believes in a collaborative process that will ensure your needs are met and nothing is left to chance.